Shop Okoume

1 - 7 of 7 results for Okoume

-

OKOUME Lloyds BS-1088 3 PLY SKU# OKO011-JOUB-FSC Size: 3mm x 48" x 98" -

OKOUME Lloyds BS-1088 3 PLY SKU# OKO012-JOUB-FSC Size: 4mm x 48" x 98" -

OKOUME Lloyds BS-1088 5 PLY SKU# OKO020-JOUB-FSC Size: 6mm x 48" x 98" -

OKOUME Lloyds BS-1088 5 PLY SKU# OKO028-JOUB-FSC Size: 9mm x 48" x 98" -

OKOUME Lloyds BS-1088 11 PLY SKU# OKO042-JOUB-FSC Size: 15mm x 48" x 98" -

OKOUME Lloyds BS-1088 11 PLY SKU# OKO047-JOUB-FSC Size: 18mm x 48" x 98" -

OKOUME Lloyds BS-1088 13 PLY SKU# OKO055-JOUB-FSC Size: 25mm x 48" x 98"

- Seattle-Tacoma woodworkers and boatbuilders, elevate your projects with okoume marine plywood from Edensaw Woods! We're your trusted local marine plywood and panel supplier for home builders, furniture manufacturers, and boatbuilders in the Seattle-Tacoma area. Discover the exceptional quality and beauty of okoume marine plywood for your next project. Explore our wide selection of marine plywood, such as ceiba marine plywood, hydrotek marine panel, and sande marine panel. Visit our location or browse our online inventory to find the perfect piece for your project. Our knowledgeable staff is here to assist you with expert advice and personalized service. Okoume marine plywood is a premium-grade panel product sourced from the okoume tree (Aucoumea klaineana), native to West and Central Africa. Renowned for its lightweight nature, excellent durability, and water-resistant properties, it's the perfect choice for high-performance marine construction and boatbuilding.

Features and Benefits of Okoume Marine Panel:- Lightweight Performance: Okoume is one of the lightest marine plywoods available, making it perfect for applications where weight saving is critical, such as the construction of high-speed boats, racing dinghies, and lightweight structural components. Its density is typically low, ranging from 0.40 to 0.50 g/cm^3.

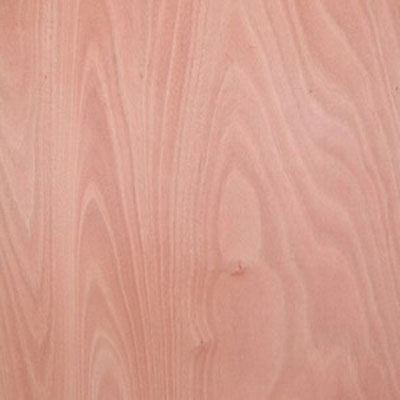

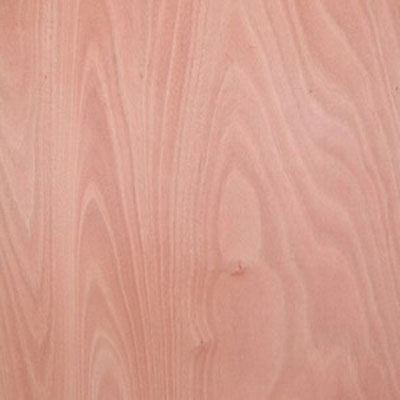

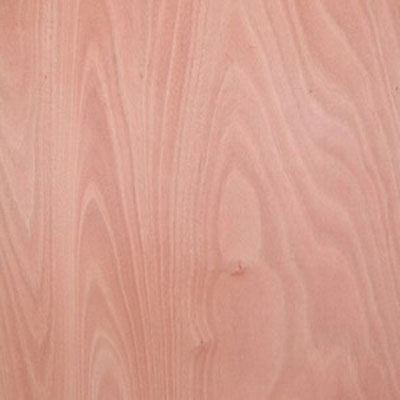

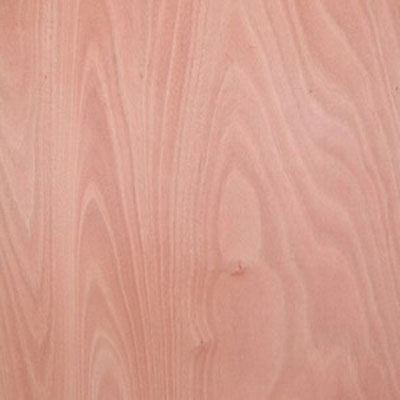

- Aesthetic Appeal: Okoume has a beautiful light brown-pink hue and a fine, uniform texture, making it appropriate for both structural and aesthetic applications, especially when a clear marine finish is applied.

- Stability and Durability: It has little swelling and shrinkage, ensuring dimensional stability even when exposed to changing moisture levels. While lightweight, it is durable, especially when properly encapsulated with marine-grade varnish or epoxy.

- Workability: Okoume is known for being easy to cut, drill, and shape using ordinary woodworking tools, and its uniform consistency makes it ideal for scarfing and epoxy layups.

- Wood Source: Wood comes from the okoume tree, which is endemic to tropical West Africa, specifically Gabon, Equatorial Guinea, and Congo.

- Core and Veneers: The plywood is manufactured by layering thin okoume veneers, which are joined together with a waterproof glue to ensure longevity in marine settings.

- Waterproof Bonding: Okoume marine plywood uses WBP (water and boil proof) phenolic adhesive and is resistant to water and humidity, making it ideal for maritime applications.

- Void-Free Construction: Marine-grade plywood must be certified to standards like BS 1088 (British Standard), ensuring it is free of voids and imperfections in the core. This construction is crucial as it reduces water ingress and structural failure in marine areas.

- BS 1088 Certification: The best okoume plywood carries the BS 1088 stamp. This is the global benchmark, certifying the panel uses WBP glue and has virtually no internal voids or core gaps. Always verify this certification for any structural marine application.

- Epoxy Encapsulation: Due to okoume's lower natural decay resistance compared to woods like teak or meranti, it is highly recommended to fully epoxy encapsulate all edges, faces, and screw holes when used in boat hulls or areas of constant exposure. This process seals the wood, maximizing its lifespan and structural integrity.

- Structural Thicknesses: Okoume is commonly specified in thicknesses ranging from 1/8-in (3mm) for light non-structural sheathing up to 3/4-in (19mm) for bulkheads and structural flooring. The choice of thickness is dependent on the boat's design and engineering requirements.

- Finishing for UV Protection: While epoxy encapsulation provides a moisture barrier, it requires a topcoat of varnish or marine paint containing UV inhibitors to prevent the epoxy itself from degrading under sunlight.

- Boat Building: Because of its lightweight and water-resistant characteristics, it is commonly used in the construction of boat hulls (especially stitch-and-glue construction), decks, and interior fittings for kayaks, canoes, and small yachts.

- Furniture & Cabinetry: Okoume is used to make lightweight furniture and cabinets, particularly in marine vessel interiors or high-humidity areas, due to its low weight and stability.

- Exterior Projects: In addition to nautical applications, okoume is sometimes used in exterior structures such as gazebos or soffits, though it must be properly sealed to prevent against weathering.

- Strengths: Lightweight, moisture-resistant (when sealed), easy to work with, and aesthetically appealing grain.

- Weaknesses: Okoume is a softer wood than other hardwood marine plywoods (such as meranti or hydrotek), making it more prone to surface wear and tear, impact damage, and rot if the protective finish is compromised.

- Sealing and Finishing: To ensure its lifespan, okoume marine plywood must be thoroughly treated with marine-grade varnishes, paints, or epoxy coatings. When not sealed, it is prone to moisture damage and surface degradation. For outdoor use, a UV-resistant treatment is required to avoid sun damage over time.

Searching for premium, durable okoume marine plywood in the Pacific Northwest? Edensaw Woods (Edensaw.com), your local marine plywood and panel supplier in Port Townsend-Tacoma, Washington, is your source for high-performance specialty wood. We offer a wide selection of top-quality marine plywood and panels, including the lightweight, superior okoume grade, which adheres to the strict BS 1088 standard. Crafted from fine okoume veneers with a waterproof phenolic resin glue, okoume is perfect for lightweight boat hulls, interiors, and decks. Our marine inventory also includes ceiba, hydrotek, sande, and tripanel, often available in thicknesses starting around 1/4-in. Serving the Seattle-Port Townsend-Tacoma area, Edensaw provides both products and services to meet the demands of any marine or cabinet project. Contact us today to discuss your material needs, or tell us about your completed project! - Lightweight Performance: Okoume is one of the lightest marine plywoods available, making it perfect for applications where weight saving is critical, such as the construction of high-speed boats, racing dinghies, and lightweight structural components. Its density is typically low, ranging from 0.40 to 0.50 g/cm^3.

Pack Quantity

The quantity that makes up a standard package.

You must order in units of this quantity.

Items are sold in Gross and Pieces.

Example: Package quantity

- .3333 gross enter .3333

- 10 gross enter 10 or 20, 30 etc.

- 72 pieces enter 72 or 144, 216 etc.

Please note: 1 gross = 144 pieces.

| Pack Quantity | Pieces |

|---|---|

| 0.0208 | 3 |

| 0.0417 | 6 |

| 0.0555 | 8 |

| 0.0625 | 9 |

| 0.0694 | 10 |

| 0.0833 | 12 |

| 0.1041 | 15 |

| 0.1111 | 16 |

| 0.1250 | 18 |

| 0.1389 | 20 |

| 0.1667 | 24 |

| 0.2083 | 30 |

| 0.2222 | 32 |

| 0.2500 | 36 |

| 0.2778 | 40 |

| 0.3333 | 48 |

| 0.4166 | 60 |

| 0.5000 | 72 |

| 0.6667 | 96 |

| 0.7500 | 108 |

| 1.3333 | 192 |

| 1.5000 | 216 |

| 1.6667 | 240 |