Edensaw Woods is the Evergreen State's top provider of

high-quality marine-grade plywood for home construction, woodworking, and remodeling projects. We have professional and qualified employees who can assist you and answer any questions you may have about whether a certain marine-grade panel is suitable for your woodworking project, from furniture to DIY home construction. At Edensaw, you can find a wide selection of top-grade marine-grade plywood, including ceiba, meranti, okoume, sande, teak, tripanel, and many more.

Marine-Grade Panels Supply in Washington State: Marine-grade plywood and panels are a sought-after product for furniture makers, woodworkers, and home builders across North America and the Pacific Northwest. Marine plywood is typically manufactured from moisture-resistant hardwood veneers that are glued together with waterproof adhesives (WBP - Weather and Boil Proof). The manufacturing process increases their strength and resistance to warping, splitting, and delamination. This resilience ensures that furniture, woodworking projects, and home structures made from marine-grade plywood and panels will last longer and can endure the rigors of different, often damp, conditions.

The Standard for Marine Plywood: BS 1088 - True marine plywood must adhere to strict international standards for quality and performance:

- BS 1088 Certification: The definitive standard for marine plywood is British Standard BS 1088. This certification ensures the plywood is made with only the highest quality wood species and is guaranteed to be 100% void-free in the core. Voids in the core are air pockets that can trap water and quickly lead to rot and delamination, making them unsuitable for shipbuilding.

- Adhesive Quality: Marine plywood must use exterior-grade, highly water-resistant adhesive, typically phenolic resin. This type of glue ensures the layers remain bonded even when submerged or exposed to constant high humidity.

- Veneer Grade: The internal and external veneers must meet a rigorous quality standard, often defined as A-A or A-B grade, meaning the veneers are strong, defect-free, and of an appropriate species for humid environments.

The most popular marine-grade plywood and panels in North America:

Douglas fir plywood is a common choice for marine-grade applications due to its structural strength and dimensional stability. It has a high strength-to-weight ratio and is resistant to moisture, making it perfect for boat construction and outdoor work.

Teak plywood is known for its inherent resistance to rot, insects, and wetness. Teak plywood is in high demand because of its beautiful appearance, toughness, and lifespan. It is frequently utilized in the interiors of high-end yachts and boats.

Okoume plywood is lightweight, easy to work with, and resistant to both moisture and rot, and commonly found in applications for boat construction, outdoor furniture, and cabinets.

Sande plywood is a cost-effective option that provides good strength and resistance to moisture. It is commonly used in marine applications such as boat flooring and substructures.

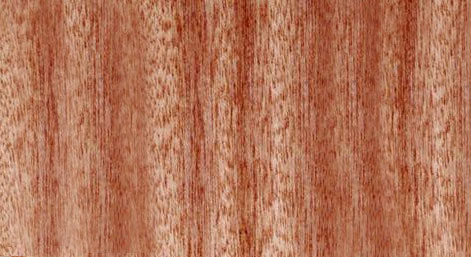

Meranti plywood is a high-quality marine-grade plywood known for its exceptional durability and resistance to moisture. It is made with a durable face and core veneers and features a waterproof glue bond.

Ceiba plywood is lightweight, robust, and moisture resistant. It is extensively utilized in the production of boats, interior panels, and furniture.

TriPanel is a composite marine plywood panel that combines a plywood core with fiberglass reinforcement on both sides. It offers excellent strength, stiffness, and water resistance, making it suitable for boat hulls, decks, and bulkheads.

Key Applications for Specialty Marine Panels - The superior quality of marine panels makes them ideal for environments where standard wood products fail:

- Boat and Yacht Building: Essential for hulls, bulkheads, decks, and interior joinery where structural integrity and moisture resistance are non-negotiable. Lightweight panels like Okoume are highly valued for racing boats and canoes.

- Exterior Architecture: Used for exterior signage, outdoor kitchens, and architectural millwork in coastal or high-humidity regions where exposure to moisture is constant.

- Sub-flooring and Underlayment: Ideal for basement sub-floors, shower compartments, or other areas prone to accidental flooding or continuous moisture exposure.

- Cabinetry in Humid Environments: Used for building cabinets and fixtures in bathrooms, laundry rooms, or marine galleys where condensation and high ambient humidity are concerns.

Do you need marine-grade plywood for your projects? As your local marine and cabinet grade plywood supplier,

Edensaw Woods (

Edensaw.com) offers a wide selection of top-quality

marine plywood and panels essential for boat building, exterior construction, and humid environments. From our locations in Port Townsend-Tacoma, Washington, USA, we provide professionals and hobbyists in Seattle-Port Townsend-Tacoma and the nearby Pacific Northwest region with premium, water-resistant panels. Browse our diverse inventory, which includes specialized marine panels like high-strength

ceiba, durable

meranti, lightweight

okoume, dependable

sande, and versatile

tripanel, among many more options. As a local domestic & exotic supplier, we also offer a wide array of

products and

services; please

contact us for assistance with your marine-grade material needs.